- +91 96992 27332

1

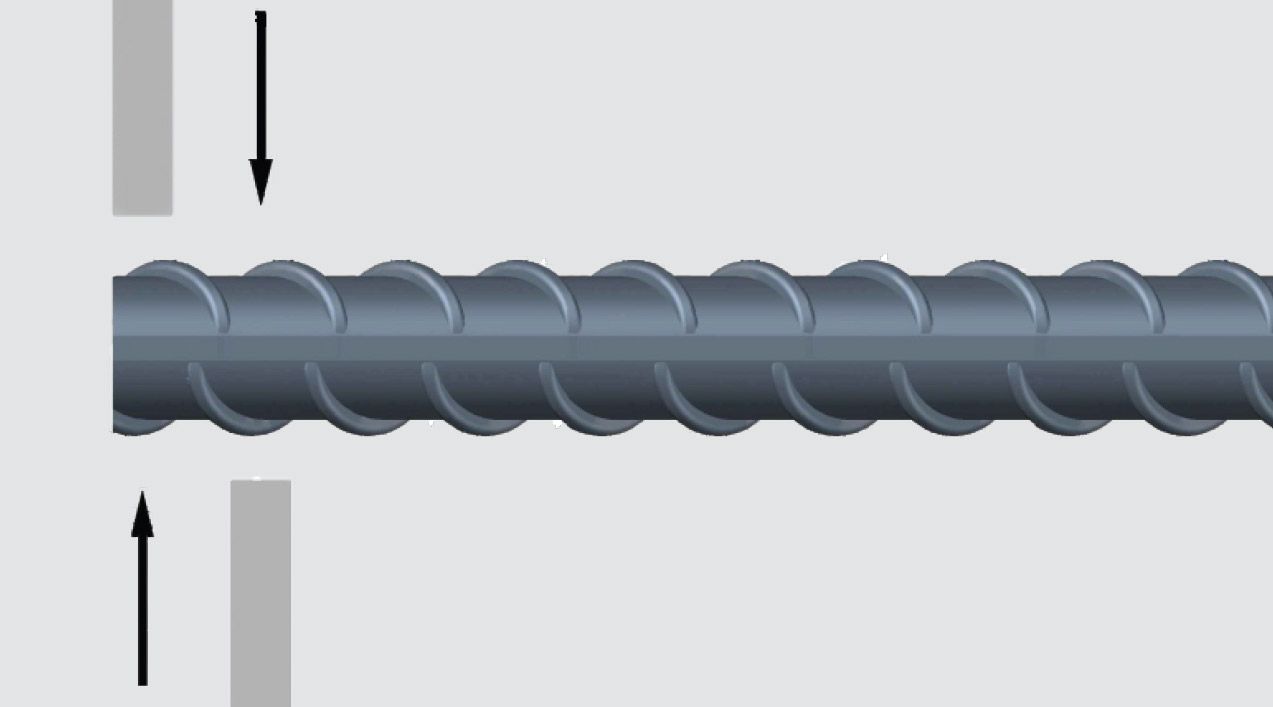

Cutting / Shearing of Rebars

The Bars with improper ends like bent, too much heated, improper manufactured ends etc., are cut with Band saw machine. This is done in order to achieve a approximate Flat face for further forging of the Rebar.

2

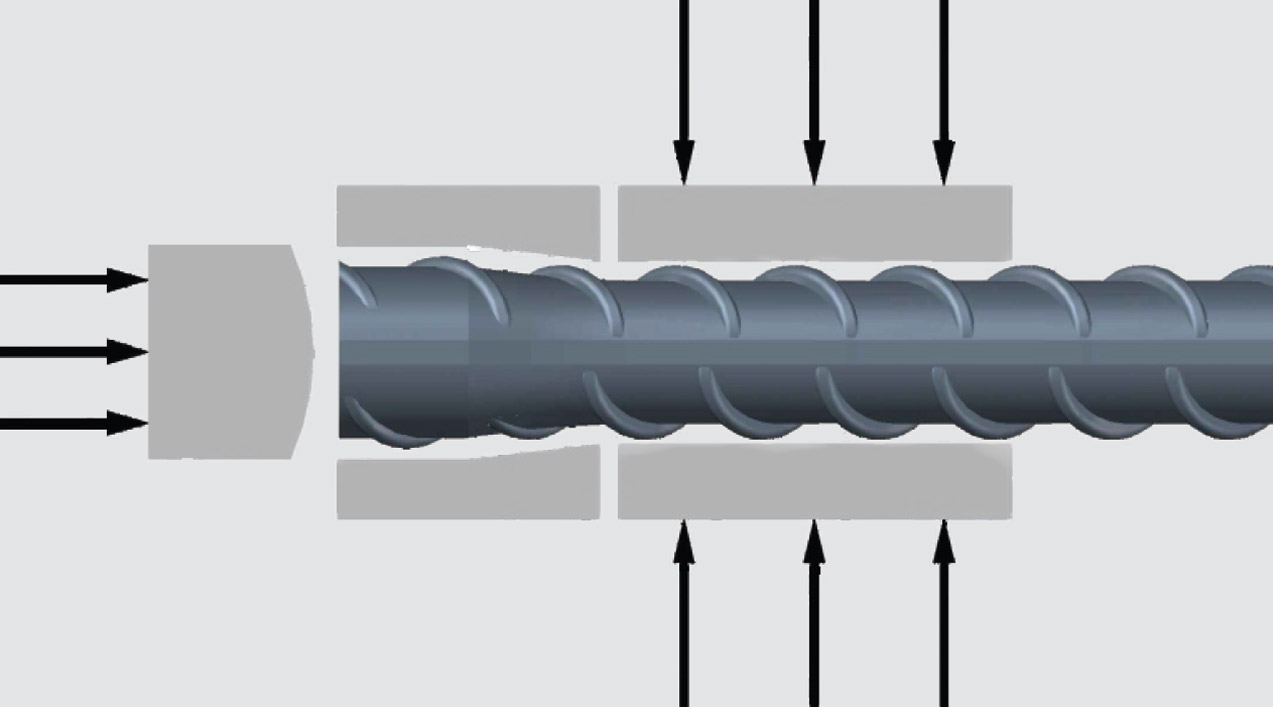

Forging of Rebars

The Bars with improper ends like bent, too much heated, improper manufactured ends etc., are cut with Band saw machine. This is done in order to achieve a approximate Flat face for further forging of the Rebar.

3

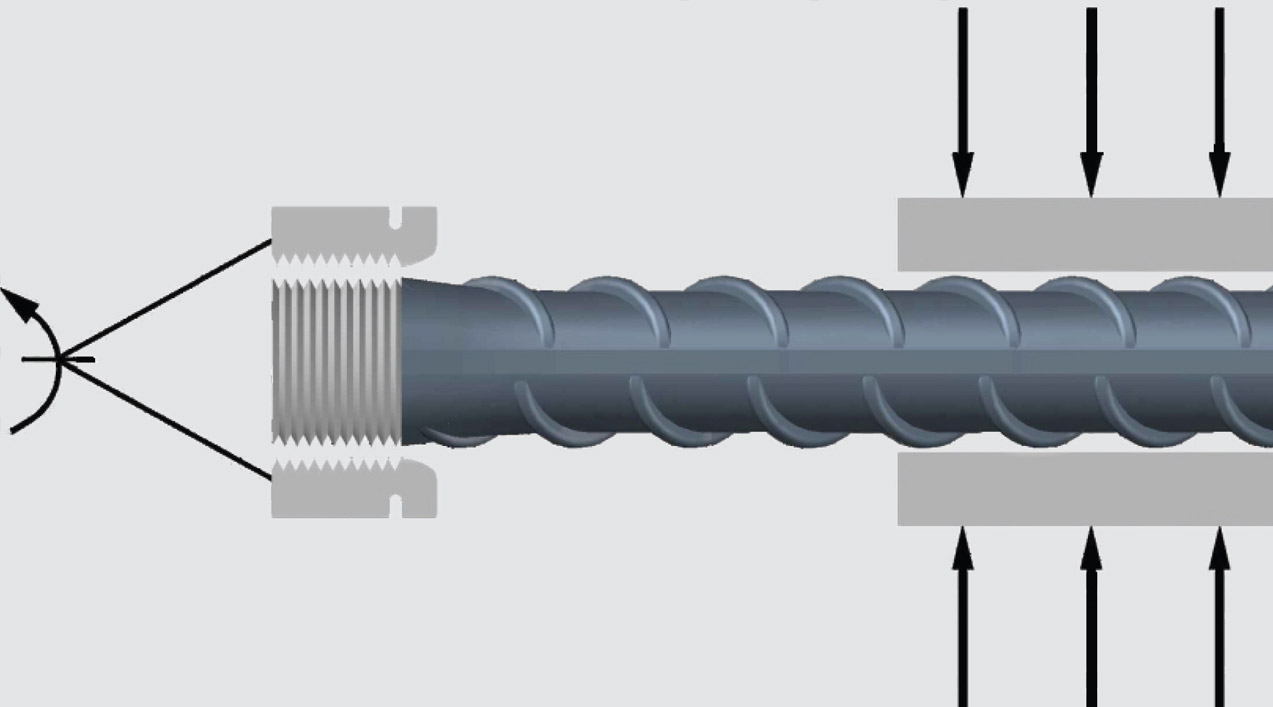

Threading of Rebars

The Forged end of the bar are then threaded with a threading machine, the machine consists of 4 chasers, which generate the needed thread profile on the bar end. The threads are then checked with a GO Gauge & NO-GO Gauge. Depending on site conditions, the threaded ends are stored for further site installation

We Provide 16mm to 40mm Coupler, for which Specifications are given below:

| Rebar Dia(mm) | Forged Dia(mm) | Approx % Increase | Approx Pressure Apllied in BAR |

|---|---|---|---|

| 16mm | 20mm | 24% | 80-90 |

| 20mm | 24mm | 20% | 100-120 |

| 25mm | 30mm | 20% | 150-170 |

| 28mm | 32mm | 18% | 220-230 |

| 32mm | 36mm | 12% | 250-270 |

| 36mm | 40mm | 12% | 280-320 |

| 40mm | 45mm | 12% | 300-320 |